Quality Assurance

Committed to Exceptional Quality

Ensuring the quality of our Services and Products is essential, whatever our industry or sector, to maintain customer loyalty. Additionally, our organization needs to be able to deliver quality services and products in a reliable and sustainable manner to maintain and increase its market share.

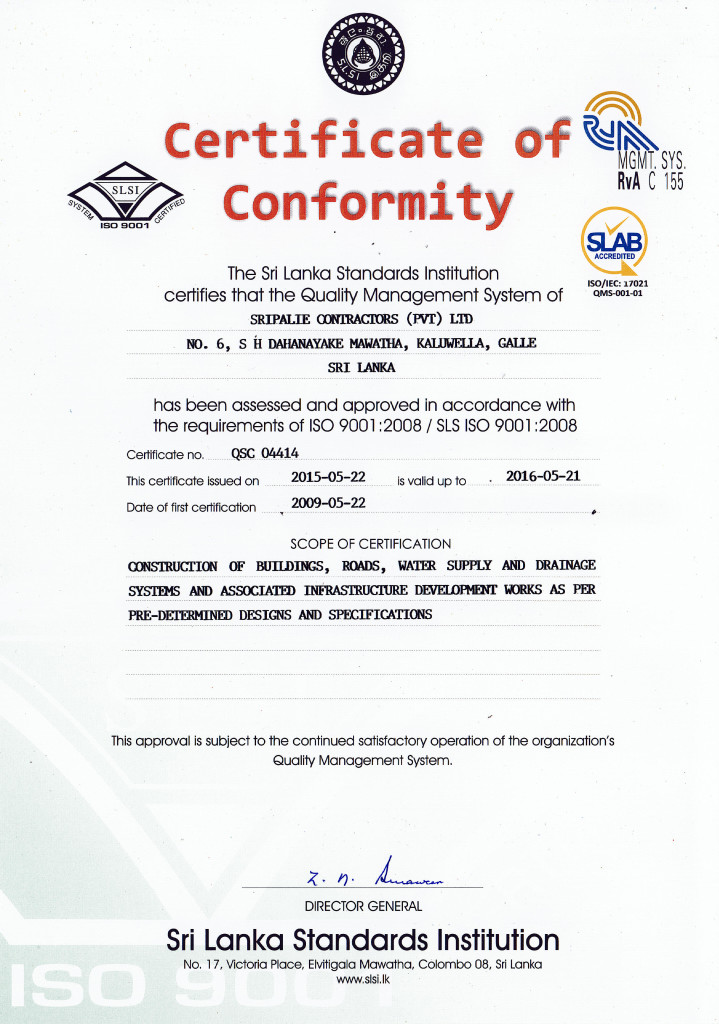

At Sripalie, we know that quality management is a continuous process, involving implementation, maintenance and improvement. Whatever our sector, our business will benefit from a quality management system that brings us into line with international standards.

Our Quality Management System has been certified under ISO 9001: 2008 for Construction of buildings & Associated Infrastructure development work, roads, water supply & drainage as per Pre-Determined designs & specifications.

A Quality Assurance or a Quality Control system (depending on the specific requirements of each project) is established to perform sufficient inspection

and tests of all items of work, to ensure conformance to the applicable specifications with respect to the materials, workmanship, construction, finish, functional performance and identification. These controls cover all construction processes and operations including design and fabrication, and is linked to the Critical Path Management utilities of the project.

According to the General Quality Plan and specific quality plan, it should be properly filled and signed relevant forms before carrying out each activities in construction sites. There by any mistake in the procedure will be checked and corrective action will be taken.

There are special procedures to ensure the material quality at sites. Supplier evaluation is effectively helpful to maintain the quality of material.

The workmanship is categorized according to their skills and competencies. This also helps to maintain the high quality finishes of product.

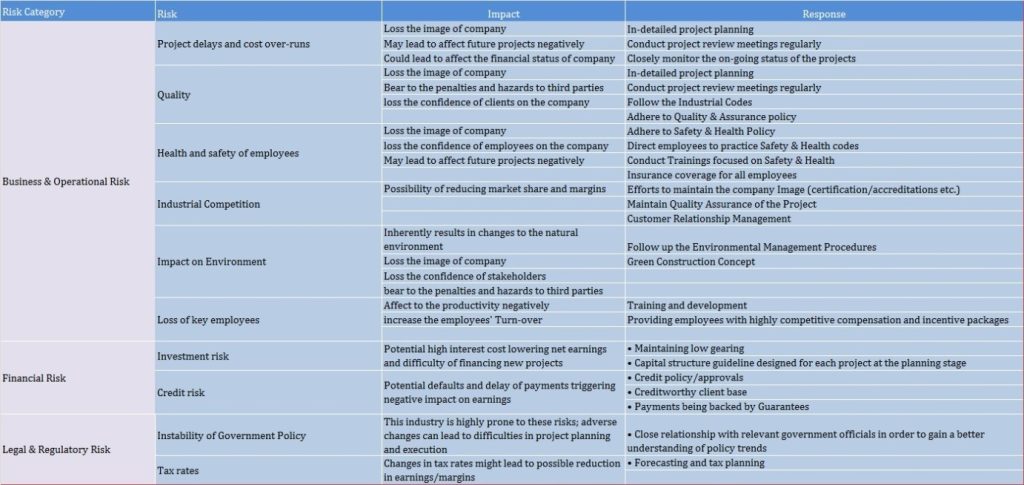

Risk Management

Risk management has always been a key priority within the Sripalie’s strategic decision making process as it forms the bedrock to the entity’s sustainability and business continuity. Risk management is embedded in the organization’s management practices, culture and values. Sripalie Contractors’ culture and value system emphasize the dichotomy of risk management and the need to take risks in astute fashion, while transforming them into opportunities and therefore advantages for business, whenever possible.

The effectiveness of risk management is measured by the achievement of organizational goals and objectives. The success and sustained growth seen at Sripalie affirms the efficacy of our risk management initiatives, despite operating in unstable and competitive settings.

Risk management strategies are employed based on constant analyses, reviews and previews conducted in various areas of the Industry as well as the organization which gain an unrelenting focus on risk potential and solutions. The strategies implemented are most often triggered through experience and infuse strategic planning processes and best practices to minimize, prevent or assuage risk.

The broad categorization of some of the key risks identified as applicable to the organization and which are deemed relevant to the current reporting period.

Knowledge & Skill

Our Building Blocks of Excellence

From origin, Sripalie has recognized the vital role that human capital plays in reaching out corporate goals aligned to the company’s vision. Sripalie Contractors (Pvt) Ltd initiated its business in 30th years in local construction industry without behaving second to the largest construction companies in Sri Lanka. In initial step, we faced some obstacles in recruiting well Qualified & Experienced personnel as well as upgrading their knowledge & Skills to meet the requirements of fast-growing in the industry. However, today job market consists of employees with well Qualified & Experienced personnel as well as so many opportunities exist for them to improve their capabilities. Hence, we practice “Right personnel for Right positions” in recruiting level. This procedure was facilitated to grow up & maintain proper Human Capital in the company as well as continuity of having Training & Development, has being facilitated to maintain an Quality Workforce with the strength of meeting the requirements of this fast-growing industry.

Key Services

- Electrical Installations

- Aluminum Fabrication

- Air Conditioning

- Improvement & Maintenance

- Design & Building

- Consultancy Services

Key Area

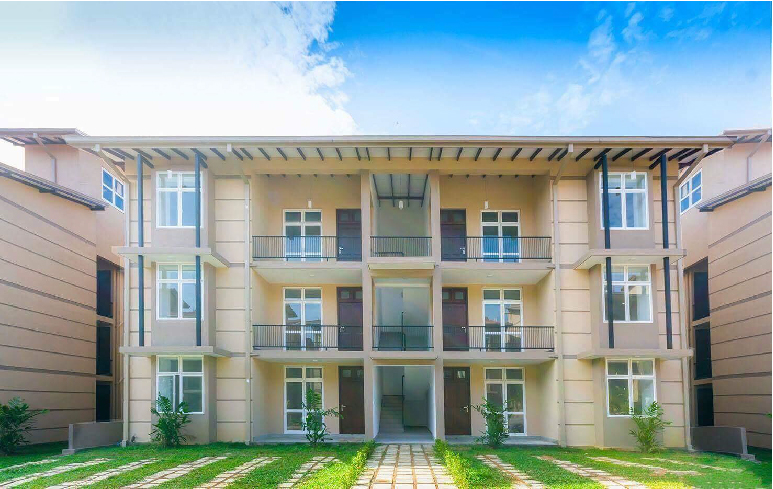

- Hotel Buildings

- Commercial Buildings

- Residential Buildings

- Hospital Buildings

- Sport Complexes

- Factory and Warehouse

- Institutional Buildings

raining & Development has a straight-line impact on the success of Sripalie Contractors (Pvt) Ltd. The company continually invests on Training & Development of both Technical & Soft skills which are essential for sustainability in fast-growing of present context. Without investing on Training & Development, we could not be competed with rivals. We highly focus on expanding & improving the Skills, Knowledge & Attitudes of employees while we are investing on Training & Development.

Apart from Improving Skills, Knowledge & Attitudes, eventually we expect employees to take over the responsibility in the Decision Making Process over the Training & Development.

Safety & Health

Our Top Priorities on Every Project

Sripalie Contractors has very strong commitment to Health & Safety and has extensive systems in place to ensure continuous improvement and the protection of the Health & Safety of its staff, client and consultants and the general public.

The Sripalie Contractors commits to an Occupational Health & Safety policy statement and specific and relevant safe work procedures. To achieve peace of mind and compliance with statutory requirements, the Sripalie Contractors include:

- A Health & Safety Management Plan.

In implementing this policy, we comply not only with the requirements of the relevant legislations, but also promote appropriate measures for the protection of Health & Safety.The objectives of this policy are:

- Prompt accident notification investigation and reporting.

- The establishment and maintaining of healthy, safe and productive working environment.

- Protection of property equipment and material from all down grading incidents.

- Protection of environment by removing all hazardous wastes and by proper housekeeping.

- The integral part of effective management in construction is awareness that high standard of Health, Safety & Environment is required.

- The HSE committee should be establish at each working location in order that, full consideration can has been taken place between employees and management to ensure that employee derive the maximum advantage from Health, Safety & Environment standard, set in herewith.

- There should not be any employee to be found to have been negligent in the matter of Health, Safety & environment or have contributed to accident through personnel neglect, the that person will be subjected to a disciplinary procedure which could result in dismissal.

ZERO ACCIDENT TOLERANCE POLICY

All endeavors to any occurrence threaten the Health, Safety & Environment of our workforce and the general public. The management is committed to achieving and sustaining” ZERO ACCIDENT TOLERANCE” through continues improvement practices.

Objectives;

- No workplace injuries and occupational diseases.

- No accident.

- Promote HSE as an integral part of our day-to-day activates.

- Enhance employee awareness and involvement in Health, Safety & Environment program implementation.

- Optimize the use of continuous improvement practices as the basis for “Zero Accident Tolerance” initiative.

- Eliminate all Environmental impact aspects.

- A documented incident or accident investigation procedure.

- Full compliance with the “Code of Practice: First Aid” with a company policy that multiple members of any team are to be trained and qualified in First Aid.

- A contractor and consultant assessment process to evaluate, amongst other things, the skills and competency and commitment of contractors to carry out work in safe manner.

- A customized return to work plan for injured employees as required.

- Induction of all staff into Sripalie Contractors safety procedures and annual refresher training sessions.

- An annual review of the effectiveness of the Sripalie Contractors Health & Safety Systems and their performance.

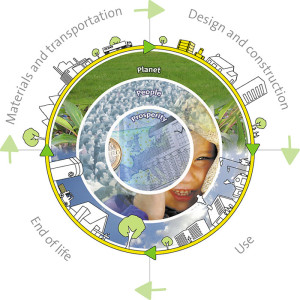

Sustainability Approach

Building a Greener Future Together

We consider our existence to be as important as the existence of all other entities on the planet and all the entities that will inhabit it in the future. Therefore Our Sustainable Approach aims at reducing the environmental impact of a project over its entire lifetime, while optimizing its economic viability and the comfort and safety of its occupants.

While standard building practices are guided by short term economic considerations, sustainable construction is based on best practices which emphasize long term Affordability, Quality and Efficiency. At each stage of the life cycle of the building, it increases Comfort and Quality of life, while decreasing negative Environmental Impacts and increasing the Economic Sustainability of the project. Any project designed and constructed in a sustainable way minimizes the use of Water, Raw materials, Energy, Land … over the whole life cycle of the building.Sustainable construction also helps achieve gains in human Health and Prosperity.

- Best-practice construction, procurement and supply chain integration.

- Procurement specifications to exactly match requirements and pre-testing of samples undertaken.

- Procurement from reputed, standardised suppliers

- Natural products (e.g. sand, metal and blocks) bought only from environmentally friendly and ethical sources.

- Timber, steel and aluminium waste brought down to near zero by bulk ordering of cut lengths

- Precautions taken to prevent illegal discharge of waste into ground water

- Filtering and chlorination at RMC Plant

- Solid waste separated and disposed into dumping yards

- Timber off-cuts reused as firewood by workers

- Focus on reducing noise, dust and waste water.

- Dust screens used to prevent air pollution.

- Low noise generators used and any noisy operations disallowed beyond 6.00 p.m. in order to ensure minimum noise pollution.

- Sites covered up by investing in netted enclosures and fences to improve the appearance of the environment and hide ongoing construction.

- Hiring of skilled and unskilled staff from the local community (20% – 30%)

- Materials procured from local agents of our approved suppliers even at higher prices, to involve and benefit the local community.

- Recruitment of staff from the locality and retention through our subcontractors.